When it’s no longer needed, the plastic starts eating itself from the inside.

Most “compostable” plastic won’t break down easily in a backyard compost bin. And the process can take so long at an industrial composting facility that many facilities that take food waste refuse the compostable plastics altogether (and that’s if your city has curbside pickup for compost—most don’t). So it’s not uncommon, then, for a compostable fork or cup to end up in a landfill, where it won’t break down any faster than ordinary plastic, or in a recycling facility, where it can contaminate recycling.

But at a Bay Area-based startup, scientists are developing a bioplastic that breaks down differently, making it possible to compost it at home. “We’re basically degrading these materials from the inside out, rather than what typically happens in a compost facility, which is the product degrading from the outside in,” says Aaron Hall, a former UC Berkeley doctoral student who launched the startup, called Intropic Materials, using technology he worked on at the university.

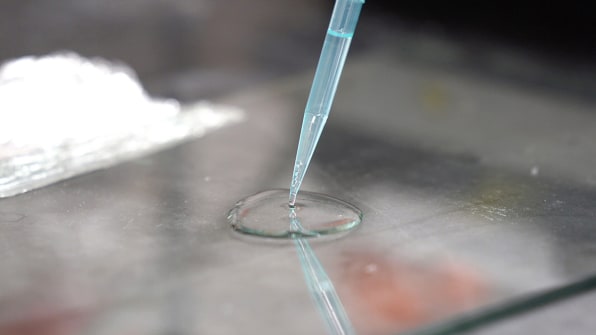

Normally, microbes use enzymes to slowly break down biodegradable plastic. “It’s sort of like taking a pair of scissors and cutting out a bowl of spaghetti—you’re just kind of cutting random noodles and making random pieces,” Hall says. In the new material, the enzymes are built into the plastic itself. When the plastic is ready to be discarded, with the right combination of heat and water, those enzymes are activated. “Since it’s trapped inside the plastic, it grabs hold and starts pulling the polymer chains one by one, cutting them into small molecules that are really easy to break down by microbes,” he says. The embedded enzymes break down the plastic more completely by going from one polymer chain to the next, rather than breaking down the polymer in random areas; no microplastic remains.

The material can degrade within days or weeks, depending on the type of plastic and temperature of the compost, according to a study published this spring in Nature. Other biodegradable plastic can take months to break down in an industrial facility. The speed of the new process makes it more likely that composting facilities would be willing to accept the material. “Composters are very much velocity-driven businesses,” he says. “They can have very slim margins, and they really need to be turning over product quite quickly.”

Because the material can also be composted at home, it makes it more likely that it will, in fact, be composted and not thrown away. (The compostability could also help in developing countries that don’t yet have industrial composting infrastructure.) It also breaks down in a hot water bath, and because it breaks down into monomers, the simple building blocks of plastic, it could also be recycled rather than composted. Hall envisions that cafeterias, stadiums, or other large facilities might eventually have an on-site system to degrade the material and then send the monomers back to be recycled into new plastic in a closed loop.

Hall currently has a fellowship at Activate, a two-year nonprofit fellowship that helps science entrepreneurs launch businesses. After demonstrating that the plastic can be composted in lab conditions, the next step will be validating the performance in the real world. The company will also work to optimize the plastic for the needs of future customers. It plans to begin with alternatives to plastics that can’t normally be recycled, like plastic films and bags. Brands are looking for solutions like this, Hall says. “Most of them don’t have the resources to really do the deep science and core innovation work that you need to do in order to solve problems like this, the kind of work that typically happens in universities and sort of basic research facilities,” he says. “And so they’re looking at it, and they’re really excited about the potential.”