Communities throughout St. James, St. John the Baptist, and Louisiana’s other “River Parishes”—those located along the Mississippi between New Orleans and Baton Rouge—shoulder some of the worst impacts of industry in the U.S.

While most of the nation’s residents live with a cancer risk of around six to 25 in a million, throughout this region, cancer risks run significantly higher, reaching 2,000 in a million in part of St. John the Baptist Parish, where a neoprene factory, Denka Performance Elastomer, emits a constant cocktail of chemicals, including carcinogenic chloroprene gas.

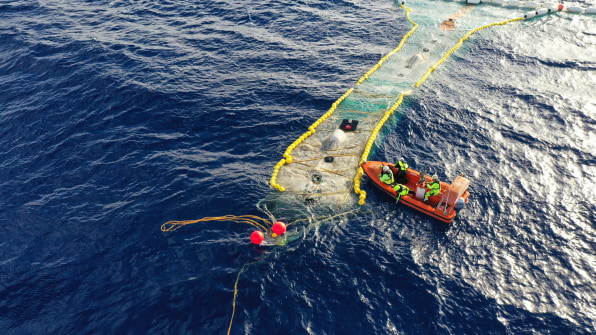

As a result, this region of Louisiana has acquired a grim reputation as Cancer Alley. In total, it is home to approximately 150 industrial plants—many of which produce chemicals used to make plastic—stretching across 85 miles of rural land, along both banks of the Mississippi. From the worst-polluted part of the Pacific Ocean, I had traced the destructive path of plastic back to a major source, in the most notoriously toxic region of America’s petrochemical landscape.

On my way to Welcome from New Orleans, in Norco, St. Charles Parish, I drove around two enormous refineries, one owned by Valero and the other by Royal Dutch Shell, and past two chemical plants, on narrow roads lined with sludgy drainage ditches slick with oil. These complexes surround Norco’s few thousand human inhabitants and their homes, shops, restaurants, post office, and places of worship. Norco was named by and for New Orleans Refining Company (NORCO), the town’s earliest industrial inhabitant, in 1916, following its purchase of former plantation land. In 1929, Shell acquired NORCO’s refinery, expanding operations significantly to include production of chemicals used to make plastic, on agricultural land I’d later learn had been wrested from the descendants of formerly enslaved African Americans who had established farms in a community called Diamond.

Diamond, which began as a small Black neighborhood, has been wracked by two lethal explosions at the Shell plant, in 1973 and 1988. Its residents have long suspected that their constant exposure to toxics was making them sick, though health officials have suggested the increased incidence of cancers and other diseases their community has seen could also be caused by smoking and other lifestyle choices. Norco’s white neighborhoods, located farther afield from the town’s most dangerous industrial operations, are less exposed.

Citizen air pollution science

Diamond once was a vibrant African American community. Today four mostly empty streets remain, running through tidy plots, many barren, a few with still-occupied homes. Diamond is a modern ghost town born out of necessity, as revealed by investigations and justice-seeking efforts spearheaded by Margie Eugene-Richard, an African American woman who grew up just 25 feet from Shell’s Diamond petrochemical plant.Having witnessed Shell’s numerous disasters striking in her own backyard, and the company’s pollution sickening close friends and family members, Richard spearheaded efforts to hold the company accountable.With the help of Louisiana Bucket Brigade, the Sierra Club, and other nonprofit allies, Richard formed a community group called the Concerned Citizens of Norco, which called on residents to gather air samples with “buckets”: low-cost, DIY research tools typically constructed from rigid five-gallon plastic containers, tubes, valves, and Tedlar bags (which are designed to hold volatile gases). Once collected, air is sent to laboratories for chemical analyses.

In 1994, personal injury attorney Ed Masry, who worked with Erin Brockovich, equipped residents of Contra Costa County, California, with the earliest iteration of these buckets to collect polluted air in neighborhoods near Unocal Corporation’s Rodeo refinery. This air-sampling effort helped reveal unchecked air pollution that had sickened thousands of people living nearby. Unocal ultimately settled an $80 million lawsuit paid out to some 6,000 residents. Since, air-sampling kits used by so-called bucket brigades have helped many communities across the US keep tabs on their local air pollution levels and hold industries accountable for violating emissions regulations.

Related: The US falls behind most of the world in plastic pollution legislationDiamond residents used their air pollution data, which revealed concerning levels of toxic chemicals, to take Shell to court, demanding relocation. During many frustrating years of litigation, Shell continued to pollute. Finally, in 2000, after Richard traveled straight to Shell’s top corporate officials working at The Hague, the company made its first buyout offer. But it was offensively low: just $26,000 per property. Richard and her allies kept pushing back to get a fair price for giving up their homes. Finally, in 2002, Shell offered to buy out Diamond’s residents—extending home-improvement loans to the few who chose to stay—and reduce its emissions, formally acknowledging that living in Diamond was too risky. Most people, including Richard, have left Diamond, though Richard would devote her life to advocating for other communities overtaken by industry in the US and abroad.

In LaPlace, St. John the Baptist Parish, a handful of cows languidly roamed a scruffy patch of dead roadside grass at the foot of the steam-ing, gleaming scaffolding of yet another chemical complex. The blue-and-white logo affixed to a large chemical storage tank read “Denka Performance Elastomer.” When I stepped out my car to get a better look at the animals, the sharp scent of industrial emissions stung my sinuses, and my temples began to throb. Almost immediately, I noticed a pickup truck outfitted with security mirrors and flashing lights rolling toward me. I hurriedly snapped a few photos of the cows—and inevitably, the plant—before returning to my car and driving on.

The expanding industrial complex

Near Garyville, approaching St. James Parish, the landscape and everything that occupied it appeared increasingly sepia toned. The streets, the fences, the houses, the electricity wires, and the grass that miraculously continued to grow—everything was acquiring a rusty tint that intensified in hue when an industrial complex came into view a few miles down the road. This one was a hodgepodge of round-topped domes, silos and pipes, and smokestacks, all coated with a layer of bauxite ore, a red claylike substance used in aluminum refining, imported from Jamaica. Bauxite dust, which often contains traces of heavy metals, is considered an occupational hazard for people who work with the ore. For miles, the clay clung to everything, even the air, which felt gritty inside my mouth. The wind carried the plant’s toxic emissions, sending mercury invisibly into the air and sweeping it across the orange landscape, where it accumulated in the soil, nearby streams and rivers, and the mighty Mississippi.I continued driving past more toxic tailings ponds, more chemical plants, more piles of industrial waste, until I reached the Sunshine Bridge. After crossing the cantilever bridge, I followed River Road past the Mosaic company’s fertilizer and ammonia factory and AmSty’s polystyrene plant to finally arrive in Welcome.When I arrived, I climbed up the grassy levee to take a look at the river. I could see a grain barge loading up against a collection of floating storage containers strapped together like a giant metal raft near the undeveloped bank—just grass and mud and twisting live oaks—most of them dead and crumbling. Upriver, I could see a tangle of thick pipes reaching across the levee and over the highway, supplying petroleum to yet another chemical plant. The site of the proposed plastic factory, an enormous acreage of over-grown grass, was cordoned off by nothing more than a tall, chain-link fence, topped with barbed wire.

Erica Cirino is a science writer and artist who explores the intersection of the human and nonhuman worlds. Her photographic and written works have appeared in Scientific American, The Guardian, VICE, Hakai Magazine, The Atlantic, and other esteemed publications. She is a recipient of fellowships from Woods Hole Oceanographic Institution, Craig Newmark Graduate School of Journalism at CUNY, and Safina Center, as well as several awards for visual art.Banner photo: Oil refineries in Louisiana. (Credit: wisepig/flickr)