I knew it was late to be calling him. But that night, with the first warm breezes rustling the curtains, I could sense the coming spring and realised he would turn 73 soon.

For more than a decade, my father and I had talked about returning to the place where he made plastics before I was born. The plant had exerted an inexplicable pull on me for longer than I can remember, since before I had kids, and even before I entered graduate school to study environmental legacy – what is passed from one generation to the next.

So I dialled. He answered quickly. When I asked whether he’d like to go with me, he didn’t hesitate. Within minutes, we had set a date. Two months later, in May 2013, we stood on the grounds of the former Union Carbide plant in Bound Brook, New Jersey, the birthplace of modern plastics.

A century earlier, in 1907, Leo Baekeland invented the first synthetic plastic in his laboratory in Yonkers, New York. Though earlier plastics had been made from plants (biomass), Baekeland’s formulation used fossil-fuel derivatives, which is now the standard.

He called his amber-hued invention Bakelite resin. It was made by reacting formaldehyde with phenol, produced from coal tar traced to fossilized plants. At the time, industrial chemists had just begun to manipulate hydrocarbons extracted from decomposed, ancient life. They would go on to synthesise new molecules by subjecting hydrocarbons to unearthly temperatures and pressures, and mixing them in concentrations and with other elements in combinations never before seen in nature.

After his backyard laboratory caught fire, Baekeland relocated in 1910 to a factory in Perth Amboy, New Jersey. By the early 1930s, he had built a 125-acre plant along the Raritan River in Bound Brook.

It was the broadcaster Lowell Thomas, the signature voice of the early 20th century, who helped Bakelite become a household name. The natural world was thought to have only three kingdoms – animal, vegetable and mineral – but in a 1937 film on the story of Bakelite, Thomas described a fourth kingdom of synthetics, which promised to free us from reliance on nature, including timber and plant mass such as cotton and wool. Baekeland’s company chose the infinity symbol as its logo and the phrase ad infinitum as its motto.

But Bakelite wasn’t infinite in the way Baekeland had intended. His synthetic resin inspired other companies and new plastics, which eventually began to compete for market share. In 1939, he sold his Bound Brook factory to Union Carbide.

In 1962, the same year Rachel Carson published Silent Spring, my father started his first job at this factory. He was 22, his black hair buzzed short, accentuating the characteristic patch of white just above his hairline. He had just graduated from the chemical engineering programme at the University of Rhode Island, and was hired even though URI did not yet offer classes in plastics production.

Union Carbide assigned him as a process engineer. Within four years, at the age of 26, the company promoted him to supervisor of their polystyrene department, a position he held for a couple years until taking over the production of phenol, formaldehyde and hexamethylenetetramine, the chemicals used to make Bakelite. They gave him a good salary and a small office with a door. When closed, it could dampen the din of the incessant machines. But he spent most days in the plant. His shirt and tie carried home the saccharine smell of styrene and Acrowax, the powder sifted onto the finished polystyrene pellets to keep them from sticking. For a time, he commuted by bicycle past the junkyards before pedalling down Baekeland Avenue. When the union went on strike, he worked the 12-hour graveyard shift. By the close of 1963, The New York Times Magazine reported, Union Carbide had made 1 billion lbs of plastic in a single year.

My father spent a decade at that job, spanning the period in which my three older siblings were born. By spring 2013, on the day we visited, only a few buildings remained. We happened to meet a uniformed employee who showed us a manhole cover bearing the Bakelite logo, the only known company artifact on-site. He had salvaged it and placed it by the central flagpole, in grass taken over by Canadian geese. It once marked a portal into the dense network of underground wires and pipes that, like roots, conveyed power and resources to the plant’s many branches. I stood between my father and the geese trying to imbue the round, rusted disc with significance. But all I could see were goose droppings.

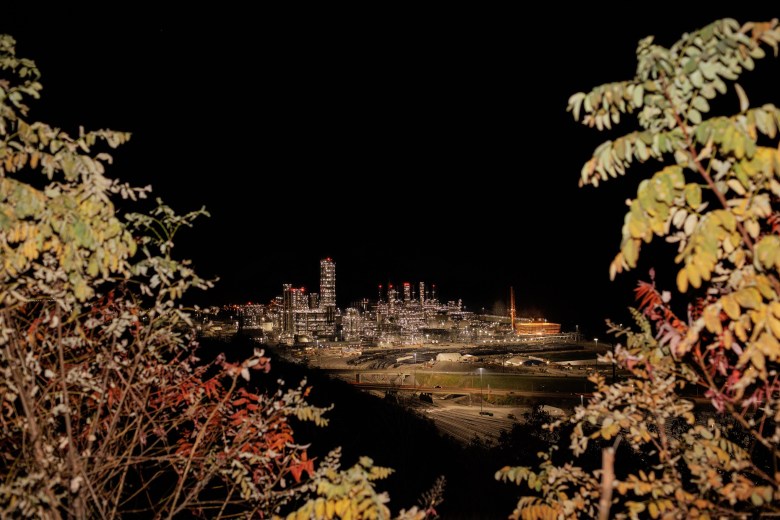

Visiting the old Carbide site made me wonder why we call industrial factories ‘plants’ in the first place. Most plants strike me as an extreme landscape, invasive, grown beyond the human scale. They look like an impenetrable thicket of pipes and valves, canopies of stacks and distillation columns with an understory of brick and catwalks, scaffolding and tanks.

But little else can thrive in their presence. I’m reminded of the Locke Breaux Oak that, since the 1600s, had grown in Taft, Louisiana. Union Carbide built a chemical plant nearby and, beginning in 1966, it likely made the styrene my father coaxed into polystyrene. When the plant was built, the oak was 36 ft around its trunk and 75 ft tall, with branches that spanned 170 ft across. But by 1968, it was dead. So I’m left wondering: how is it that two seemingly opposed concepts – factories and flora – came to share the same word?

The related term, factories, is a shortening of manufactories, an example of how places are sometimes named according to what actions – manufacturing – are performed there. Hence smelters smelt. Paper mills mill paper. Ironworks work iron. Refineries refine petroleum. But plants don’t follow the same logic. The corollary would be plantations.

Interestingly, Union Carbide’s Taft plant sits along the 150-mile corridor between Baton Rouge and New Orleans, which was once lined with antebellum plantations. The hundred or so petrochemical plants along the Mississippi were constructed on former cotton, indigo and sugar plantations, and now produce, in addition to chemical feedstocks and plastics, synthetic versions of the crops once raised by forced labour: rayon, dyes and artificial sweeteners. The descendants of enslaved peoples now share a fence line with some of the most polluting industries in the nation.

However, according to the Oxford English Dictionary, calling factories plants predates the conversion of US plantations into petrochemical production. I put the question to an environmental historian, several sociologists, a linguist, two science and technology scholars, and a plastics expert – all of whom uncovered pieces of its origins, but were otherwise stumped by how factories became plants. Might it have a Latin root? Does it refer to how the first factories converted plants (such as cotton) into commodities? Was it a clever metaphor – to plant a business, to sow profit – that spread organically? Did its use emerge in that chasm between technological change and the evolution of adequate terminology to describe it?

Even the linguist said I’d dug up an etymological mystery, one that hadn’t yet revealed its source. And while my (re)search continues, I wonder how phrases become taken for granted, adopted without thought, and their origin largely unknown to generations who rarely question the way things have come to be.

The same could be said about plastics.

My mother’s father died young, but the man my grandmother remarried – and whom I knew as Grandpa – had been among the first chemical engineers trained at the Massachusetts Institute of Technology, the first US institution to grant degrees in the field. He matriculated in the early 1920s, just as Baekeland’s business took off. He graduated with his Bachelor’s degree in 1928, and his Master’s a few years after that.

In the fall of 2012, before my father and I went to New Jersey, I visited the MIT archives. I had arranged for the librarians to find my grandfather’s theses. They were well-preserved, their black bindings so taut that they creaked when I opened them. As I read his work, I remembered his basement laboratory and how, when I was young, he had made me a set of test tubes. I’d watched as he blew bulbous ends onto slender glass tubing. I don’t remember what experiments we ran afterwards, but there were powders and liquids, scales and bottles, and shifting states and colours that seemed magical and otherworldly.

Until I read his research, I didn’t know he had experimented with corn as a feedstock. This is how I discovered that there was a time before oil, and that some industrialists of the 1930s and ’40s envisioned a radically different society, with plastics, paints and fuel for cars made from carbohydrates. But in the US by the close of the 1940s, oil had replaced both biomass and coal as the substrate for making the stuff of everyday life. Union Carbide had helped lead the conversion.

In the years since my grandfather walked these paths, all living organisms have absorbed the products of 20th century petrochemistry. We now embody its genius, its intellectual property, its mistakes, and its hubris. The US Centers for Disease Control and Prevention has confirmed the presence of at least 200 (from a possible 80,000-100,000) industrial chemicals in Americans. And though we already have clear reason for concern about their role in human health, development and reproduction, not even the scientists know exactly what their combined presence means for our future.

A generation after my grandfather studied at MIT, in the 1960s, my father oversaw four production lines of polystyrene, each capable of making 2,000 lbs an hour. Polystyrene was made in large, thick-walled autoclaves that could withstand the extremes in pressure and temperature required to string together molecules of styrene and butadiene rubber. The equipment ran round the clock, nearly every day of every year he was there. It was his job to keep the pressure and temperatures steady, lest they blow the roof. He knew styrene was hazardous, but it would be decades before the government confirmed its potential as a carcinogen.

It always struck me how the volatility my father described as inherent to plastics-making mirrored the social milieu of the decade in which he made it: the assassinations; the ignition of racism and racial inequalities in Plainfield, where he lived; and the Vietnam War – a war in which he was prepared to serve, but for a variety of reasons (his eyesight and a critical-skills deferment) didn’t. Instead, on the nightly news he watched the horrors of napalm (which Dow made from roughly 46 per cent polystyrene). While at work, he witnessed unmarked trucks cart away drums of un-reacted styrene, only to return them empty for refilling. This was before Ohio’s Cuyahoga River ignited again in 1969, before the US Environmental Protection Agency was founded in 1970, before the public health crisis at Love Canal, New York, erupted in the late 1970s, and before federal laws tried to curb hazardous waste and its burial. He knew enough to wonder where the drums – and their contents – were going, but not enough about his own agency at a time when there weren’t clear channels for questioning such things.

As my father’s discontent grew, he marched for civil rights, marched on Washington to end the war, attended the first Earth Day, and eventually, quit plastics altogether. Soon thereafter, his wife left, too, taking their kids.

By the late 1970s, US plants were making more plastic than steel. By the 1980s, Union Carbide was on its way to infamy after the lethal explosion in Bhopal, India. Meanwhile, thousands of drums containing waste from the Bound Brook plant had already been found at a farm in Toms River, an hour south. The farm was added to the federal Superfund list in 1983, the year before Bhopal. State officials later began researching whether the chemicals that had leached into the water supply from the illegal dump had contributed to elevated rates of childhood cancers.

Dow announced its intention to buy Union Carbide in 1999, even as the Toms River inquiry continued. A century after Baekeland’s invention, Dow too ceased manufacturing at the site.

When I asked my father why he left Carbide, a place many stayed for life, he said: There had to be a higher calling.

Plastic is a term that predates the material. In the 1600s, it referred to any substance that was readily moldable and easily shaped. In step with growth in plastics production, plastic acquired a figurative meaning and is now used to indicate when something seems artificial or contrived.

The landscape architect Kate Orff has written about our insatiable appetite for plastics, calling US culture a petro-topia – an idealised landscape designed for the consumption of petroleum-derived plastics, many disposable, bought on credit, which we also call plastic. It is a place distanced from the plants that make what we buy and from the communities living in the shadow of production. It is a culture built with and around hydrocarbons.

The petro-topia I’ve come to know is eerily over-populated by plants of another species: tables set with inedible fruit, backyards where grass stains have been traded for turf burns and gardens landscaped with polyethylene boulders. Where I live in Massachusetts, an artificial tree sprouts from the floor of the Whole Foods Market. It stands in the bulk-foods aisle, the freeze-dried fruit and plastic-sealed kale chips shaded from the fluorescent lights by its eternal foliage.

In one of the most telling essays on plastics, ‘Reflections of an Unrepentant Plastiphobe’ (2010), the plastics scholar Jody Roberts describes how his research made him hypervigilant about his families’ home and diet. But when his daughter was born with cerebral palsy, she was dependent on plastics for her survival. Plastic tubing conveyed breath and nourishment, even as it delivered plasticisers and other plastic additives known to interfere with vital physiological functions. His essay forced me to reconcile plastics as both life-altering and life-giving – practically inseparable from the practice of modern healthcare. We are past the point of simple dichotomies such as good/bad, nature/plastic, innocent/complicit.

It’s the same lesson taught by the new kind of rock, found recently in Hawaii. Neither plastic nor stone, plastiglomerates are a composite of melted plastics, marine debris and volcanic rock. Its discovery confirms human capacity to change the geological record for the era in which we live. According to the Worldwatch Institute, global plastics production continues to rise. Some 299 million tons of plastics were manufactured in 2013 alone, a four per cent increase over the previous year.

I’ve come to believe Baekeland chose an apt symbol for plastics. Purportedly, the infinity symbol has roots in mystical traditions. It depicts a snake eating its own tail.

Over the past 10 years, we’ve learned how sunlight and waves break down plastics into microscopically small parts. They swirl in all the oceans’ major gyres, of which there are five. In places, microplastics outnumber plankton.

Fish confuse plastics for plankton, and so plastics have entered the food chain. I’m reminded of the phrase: you are what you eat, and what you eat eats, of the snake consuming its tail, and also of the poet Adam Dickinson, who has called us a people of the resin. I suspect he is referring to how some plastic additives have come to live in us – in our bloodstreams, and even in our mother’s milk. Plastic is part of our inheritance.

This is a topic my father would rather avoid, preferring instead to talk about recycling. He tells me thermoplastics, like polystyrene, can be melted, remolded and reused. He places great faith in the possibility that some plastics could be redeemed, though in the US only about seven per cent of post-consumer plastics actually get recycled.

By the mid-1970s, my father had remarried and, around the time I was born, began a new career in public administration, where he developed a record-setting curbside recycling programme. One of the most enduring images of my childhood involves riding in his car, where he would throw litter collected from gutters and roadsides to be brought to the recycling yard. In the US, such places are called redemption centres. Recycling might be an imperfect solution to the problem of everlasting waste, but we name the place where plastic is recycled in hope of our salvation.

At its peak, Union Carbide’s Bound Brook plant employed several thousand people. On the day my father and I peered through the chain-link that now surrounds the property, there were fewer than a dozen employees left. It was spring and, in the absence of an industrial thrum, I heard birdsong.

My father’s voice cracked when we pulled down Baekeland Avenue, and he gaped in disbelief at the ghost of his old factory. We drove the perimeter, past the lot where he’d once parked. Indifferent weeds pushed through cracks in the asphalt. An old emergency vehicle still bearing the Union Carbide logo slumped in the grass. At the rear entrance, we parked where the rusted rail lines slipped under the padlocked gates, its branches warped. I tried to picture the tankers of styrene entering on one branch, the freight cars filled with polystyrene pellets exiting from another, and the trucks rumbling over the tracks with their payload of 55-gallon drums carrying away everything else. My father would never know the fate of the drums he saw leaving the plant, their whereabouts likely still unknown.

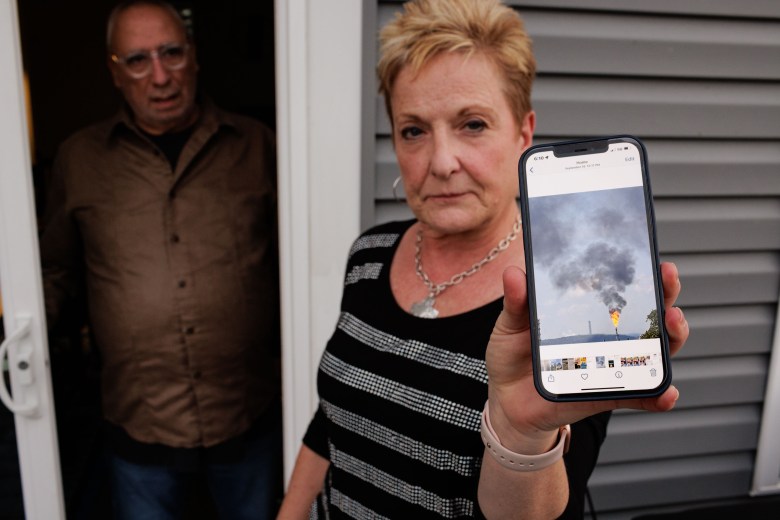

But from the papers and from Dan Fagin’s Pulitzer prize-winning book, Toms River (2013), my father eventually learned what happened to other drums that had been stockpiled at the Bound Brook plant. In 1971, in the span of just five months, a third-party waste hauler stashed at least 5,000 barrels at a farm in Toms River, the one that would become a Superfund site. The farmers, Sam and Bertha Reich, had leased their back two acres without realising the purposes to which the land would be put. They were just trying to keep the farm solvent.

Drums labeled ‘styrene’, ‘polymer solution’ and ‘chemical waste,’ as Fagin reported, were eventually found empty, others damaged and leaking. All told, an unknowable mixture of chemicals had seeped into the soil and spread to the well and fields supplying Toms River. One never-before-seen chemical was determined to be a waste product called SAN trimer, leftover from the production of acrylonitrile butadiene styrene, or ABS, a next-generation plastic that, in the late 1960s, my father remembers Union Carbide was just beginning to develop. In fact, he had witnessed its first experimental production run.

By the 1990s, the public outcry over the pollution and childhood cancers in Toms River reached its pinnacle. Cancer was already spreading in my father’s body, too. It would be another decade before it was detected. He would survive. At least 50 Toms River children, possibly more, would succumb.

The cause of any one person’s cancer is mostly unknowable, Fagin writes. And in the case of a community, it is very difficult to prove.

What happened in Toms River is a complex story. Fagin’s account, published the month before our trip, portrayed the community’s tireless but ultimately inconclusive effort to understand why so many local children had cancer. Compounding the situation was the fact that the town had also been home to Ciba-Geigy, a dye factory nestled in a pine forest along the river. For decades, it had used this river to unload its prodigious waste. The rest had been buried on site. And so, the Toms River wells, and those drinking from them, absorbed these chemicals, too. To parse what chemicals from which plant caused which cancers turned out to be a question beyond the capacity of science to answer definitely, though millions of dollars have been spent trying.

Had we not read Fagin’s book before our trip, neither my father nor I would have realised that the chemical fingerprints found at Reich Farm implicated the polystyrene department that he ran, specifically. Even though he never managed the waste, my father came to wonder whether he had unwittingly played some part in the manufacturing of what wound up in Toms River.

On the day we visited the factory, Building #91, the bulk polystyrene department, was a rectangle of barren land. It had been two stories, brick, with vaulted-ceilings, its massive production equipment housed on the top floor. The security guard connected us with two employees, who, having learned that an old-timer had come back with his daughter, escorted us on to the property to get a closer look. I stared at the footprints of old buildings as they reminisced. Before taking us back through the front gates, the facilities manager gave my father a black-and-white aerial photo of the plant. My dad named the function of each structure: the storage tanks and distillation columns, the warehouses and water-cooling station. It was nearly impossible for me to reconcile what I saw in the photograph with the landscape on which I stood. When plastics plants are shuttered, they rewild faster than I would have imagined.

Until a few years ago, plants like this were being closed across the country. Market dynamics had incentivised relocation of many such facilities to China and the Middle East. But the natural gas industry – spurred by fracking and unconventional gas drilling – might reverse that trend. Now producing abundant shale oil, gas, and ethane, American petrochemical companies are beginning to regrow their industry. From ethane, they can make ethylene, which can then be converted into styrene and other feedstocks necessary for making plastics.

‘Plants use natural gas like a bakery shop uses flour,’ said Dan Borne, president of the Louisiana Chemical Association. ‘All this stuff,’ he continued, by which he meant fertilisers and plastics, ‘starts with natural gas, our basic feedstock, our daily bread.’

After our tour of the Bound Brook plant, we turned south toward Toms River. It was happenstance that we found the Reich Farm Superfund site, tucked behind a used car shop and Carl’s Fencing, which now occupies the former farmhouse. Red, white and blue flags billowed across the place. Around the back, two rows of chicken coops stood at attention. There was nothing to see, really. No drums. No signs. The land was wild. I scanned for signs of trauma. It felt like a battleground, the kind of place people visit to reckon with their legacy, and know their place in history, except my father was anxious and wanted to leave immediately. We shouldn’t be here, he said, and steered us into an abrupt U-turn.

From Reich Farm, we drove back through town to Riverfront Landing – a small, out-of-the-way park bordered by an abandoned dental office, a through street and Toms River where it widens into Barnegat Bay. The previous fall, Hurricane Sandy had flooded the area. The park was empty, unkempt with foot-high dandelions. Litter rattled along the sidewalks.

Against a stand of shrubs leaned a stone memorial to the town’s children lost to cancer. I counted 50 names etched in multiple fonts; more had probably died after the first had been inscribed. My father approached the stone and bowed his head. He seemed at prayer.

I remember the Sundays I stood beside him in a church pew, how after communion, the congregation would join hands to recite the Lord’s prayer. Our Father, he would say, as he took my hand in his. Forgive us our trespasses. He would always hold on long after those final words.

The wind coming off the river blows an empty Kwik Mart cup to my feet. I pick it up and trace the symbol imprinted on the plastic lid – arrows cycling around the letters PS – which tell me that the lid of the cup at the cancer memorial was made from polystyrene.

In the coming weeks, my dad will consider calling the Toms River Town Hall to ask if he can clean up the park – to mow the grass, clip back the bushes, carry away the trash. The sight of a forgotten memorial was unbearable to him. He wanted their lives – and deaths – to seed what changes he feels must now come next.

A year later, I would look up the origin of plants in the Oxford English Dictionary, and instead stumble on a lesser-known meaning of plastic. For biologists, plastic refers to a species that responds quickly to environmental change, one capable of rapid evolution and self-preservation. Many species of plants exhibit adaptive plasticity, I’m told by the botanist Chris Martine.

Plasticity could well be the ironic answer to the environmental dilemmas we face after more than a century of petrochemistry: to be more plastic and willing to evolve as conditions change.

And while I still don’t understand how factories came to be plants, I’ve come to believe that manufacturing plants ought at least to live up to their name. This is the position taken by industrial ecologists, who over the past quarter-century have argued that industrial systems must acknowledge that plants are members of a biotic community, in constant, mutual exchange with all cycles, systems and living beings around it.

My colleagues in environmental sociology debate whether or not production systems can ever be benign. Standing at the memorial that afternoon with my father – where our every step scattered dandelion seeds – I wasn’t particularly optimistic, but I desperately wanted something to root for.

My father reaches into his back pocket to pull out a handkerchief. He wipes my eyes before his. We know there can’t be closure. We stay there, side-by-side, before climbing back into the car to follow the river to the sea.